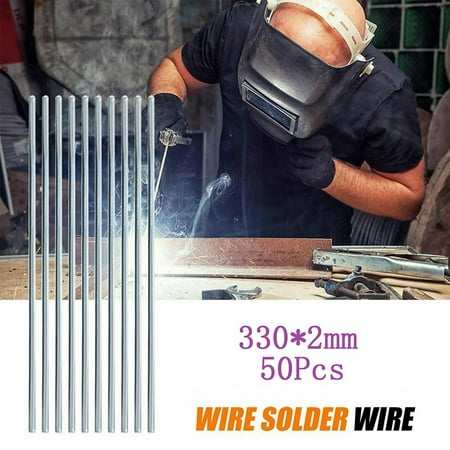

Easy Melt Welding Rods Low Temperature Aluminum Wire Brazing 10pcs 1.6mmx330mm

Description

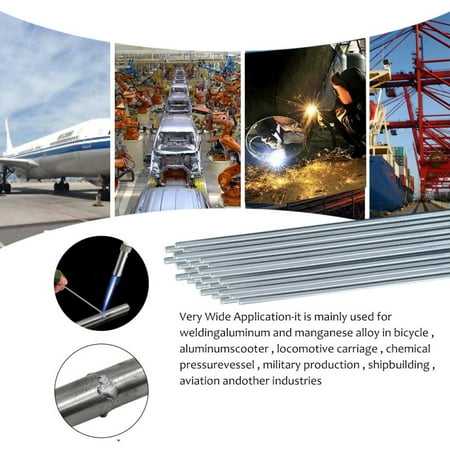

Features: brand new high quality Made of high-quality materials for durability Aluminum electrodes are pure aluminum electrodes with an aluminum content greater than 99.7%. It is a versatile general-purpose welding material. Excellent Welding Results - Welding results are plump and smooth due to the internal powder. It has low melting point (380°~400°) good weldability and corrosion resistance high thermal conductivity high electrical conductivity and excellent processability. No Sol der Powder - You don t have to use other aluminum alloy-cored base-coating flux powders. Very handy and easy to solder. Widely used in life - suitable for welding or surfacing alloys with high strength good forgeability and good corrosion resistance. It has a wide range of uses - mainly used for argon arc welding and filling materials of pure aluminum and the connection of aluminum busbars and guide rods in electrolytic aluminum plants and electric power chemical industry and food. LIGHTWEIGHT AND SMALL - 330*1.6mm in size and 3.5g in weight very easy to bend and carry. Product parameters: Quantity: 10PCS Material: Aluminum Color: silver Melting point: 380°~400° Diameter: 1.6mm Length: 33cm/1.08ft Recommended for welding or brazing aluminum alloys: 1060 1350 3003 3004 3005 5005 5050 6053 6061 6951 7005 and cast alloys 710.0 and 711.0 how to use: Step 1: Clean and polish the physical . The second step: heat the of the base metal until the temperature of the welding wire reaches the working temperature of 380℃~400℃ so that the welding seam can be formed by relying on the heat transfer welding wire of the base metal. It is not suitable to use the flame to burn the welding wire. Flows well and penetrates metal capillaries. The third step: when repairing thin aluminum as long as the aluminum base material is heated to a suitable working temperature and then the welding wire is rubbed bafor CK and forth to form the welding seam and the welding seam can only be welded with a metal brush to melt the welding wire. Step 4: Use propane gas to weld small pieces use industrial gas or induction heating device to heat and weld large pieces and cool naturally after welding. Application in life: Can be used for a variety of heat sources such as propane oxyacetylene etc. Low temperature aluminum welding wire can weld almost all white metals including aluminum aluminum cast aluminum aluminum alloys and dissimilar welding between the above metals and even serious corrosion or oil pollution to white metals and even those that cannot be repaired by aluminum alloys can be repaired. It is suitable for all-round welding of primary welders only a small heating device is needed and the strength of the weld after welding is generally higher than the strength of the base metal itself and the gas welding operation can be understood. notes: 1. The of the base metal must be clean. 2. The temperature of the base metal should reach 400 degrees including the temperature of the base metal should be kept at 400 ℃ during the welding process and the temperature can be high or low. Pafor CKage Included: 10 * Aluminum wire Note: 1.The real color of the item may be slightly different from the pictures shown on website caused by many factors such as brightness of your monitor and light brightness. 2.Please allow slight manual measurement deviation for the data.

Price history chart & currency exchange rate