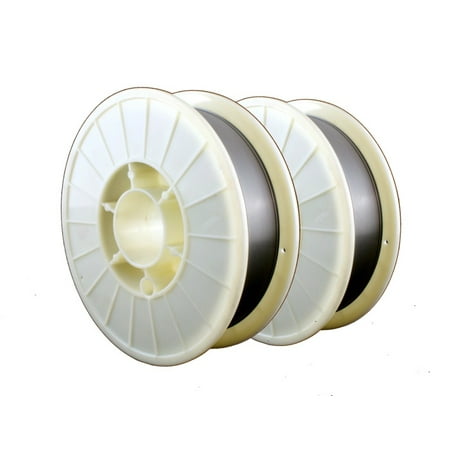

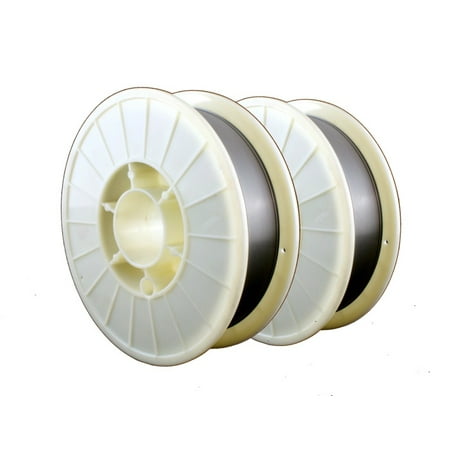

ER316L - MIG Stainless Steel Welding Wire - 11 Lb x 0.030 (2 SPOOLS)

TGB

sku: 406247577

ACCORDING TO OUR RECORDS THIS PRODUCT IS NOT AVAILABLE NOW

$209.40

Shipping from: United States

Description

ER316L - WIRE - MIG (GMAW) - STAINLESS STEEL AWS A5.9 Welding Positions: All INTRODUCTION: The main component of ER316L is 18Cr-12Ni-2Mo. It is an all position welding MIG Wire. The weld-ability is good. Feeding wire smoothly will enable stable arc excellent welding performance and spatter is very low. It has good resistance for acetic acid sulfuric acid phosphoric acid and salt corrosion because it contains Molybdenum. USES: It is widely used in petrochemical chemical fertilizer equipment such as 022Cr17Ni12Mo2 (SUS 316L) and other materials of welding. CHEMICAL COMPOSITION (%): Chemical Composition C Mn Si Cr Ni Requirement ?0.030 1.00~2.50 0.30~0.65 18..00~20.00 11.00~14.00 Typical test result 0.023 1.90 0.42 19.12 12.59 Chemical Composition Mo P S Cu Requirement 2.00~3.00 ?0.030 ?0.030 ?0.75 Typical test result 2.59 0.009 0.008 0.28 WELDING PARAMETERS (DC+): Diameter (mm) ?0.8 ?1.0 ?1.2 Welding Current (Amps) 70~150 100~200 140~220 NOTES: 1. Shield gas: Must ensure not to operate with impurity shield Gas Recommended Rate of mixed gas: Ar + 1-3% O2. 2. Operation flow rate of shield gas: 20-25L/min. 3. Electrode extension: 15-25mm 4. The welding should be operated in clean surface without rust moist oil contamination and dust. 5. To avoid bubbles protect from wind its speed reach 1.5 m/s. The above parameters are for reference purpose and depend on diverse factors. Run tests evaluate and set your welding parameters before starting the welding job.

Price history chart & currency exchange rate

Customers also viewed

$10.12

Women Headband Winter Autumn Elastic Real Rex Rabbit Fur Neck Scarf For Girls Hair Band Ladies Fashion New Design

aliexpress.com

$36.60

For BMW S1000XR 2X10 2014-2018 F750GS F850GS/Adventure 2017-2024 Motorcycle Rotatable Front Footrests Foot Pegs Pedal Foot Rests

aliexpress.com

$11.00

100 Pcs Greenhouse Glass Clamps Steel Frame Woodworking Shade Accessory Wire Cord Clips Type Glazing

aliexpress.com

$2.94

4pcs Silicone Vacuum Cans Facial Cupping Face and Body Massager Anti-Cellulite Massage Body Cups V Face Back Foot Cup Suction

aliexpress.com

$7.70

3rd Armored Division Veteran Baseball Cap Beach Outing Golf Hat Man Anime For Women Men's

aliexpress.com

$87.54

5WK96718B 22219281 5WK9 6718B Nitrogen Oxide Sensor For VOLVO EURO 6 FH4 FM4 Nox Sensor

aliexpress.com

$151.02

Multi-functional Hand Cart with Tool Box, Repair Shelf and Storage Cabinet for Auto Repair Workshops

aliexpress.com

$22.74

Irregular Shirt For Women Lapel Long Sleeves Single Breasted Solid Color Gathered Waist Shirts Office Lady Top 2DC1009

aliexpress.com

$19.23

Glass Mousepads E-sports Gaming Mouse Pad Customizable Pattern Tempered Smooth Gaming Desk Mat Fps game Office Game Accessories

aliexpress.com

$19.55

100Pcs Bulk Shoe Charms for Crocs Accessories To Catch Fish Shoes Charm for Croc Decorations Pins Men Jeans Woman Clogs Clips

aliexpress.com

$29.22

RT01 Medieval Retro Red Tuxedo Tailcoat Mens Jacket Coats Swallowtail Dust Cosplay Steam Punk Costume Palace Dress Europe Un&Gf1

aliexpress.com

$25.16

Women Black Lace Hollow Out Big Size Casual T-shirt New Round Neck Short Sleeve Fashion Tide Spring Summer

aliexpress.com

$31.61

New retro women's large capacity waterproof shoulder bag backpack Korean student y2k multifunctional nylon canvas cute backpack

aliexpress.com

$33.23

LED DRL Light For Mitsubishi Pajero Montero IV 2015-2020 Daytime Running Light White Fog Light Headlight

aliexpress.com

$3.78

Spring New Baby Baseball Cap Patchwork Color Letter Sunhat Boys Girls Summer Cotton Snapback Caps Kid Hip Hop Fishing Hat

aliexpress.com

$9.12

Car Stainless Steel Pedals Gas Accelerator Foot Rest Throttle Brake Pedal for Audi Q2 SQ2 2017-2020 AT MT Car Pedals Accessories

aliexpress.com

$20.96

Skmei Men's Sports Watch Dual Display Electronic Watch Multifunctional Luminous Waterproof Electronic Watch

aliexpress.com

$21.87

Yellow Print Spring Women Shirt Artificial Silk Ethnic Style Tang Suit Vintage Chinese Top Eleganti Loose Blouse China Clothes

aliexpress.com

$15.07

Collet designed for use with Model For 248520 Cordless Die Grinders Features Size 14inch and Part Number 48660974

aliexpress.com

$13.56

Bandage Fashion 2 Piece-Set Maxi Skirt Female Ruffled Summer Lace Elegant Streetwear Halter Top And Long Skirt Women Sets

aliexpress.com

$28.80

WT-BC253 Yellow Brass Fine Thick And Solid Heartshape Clasp Wholesale Chain Accessory For Women Necklace Making

aliexpress.com

$1.84

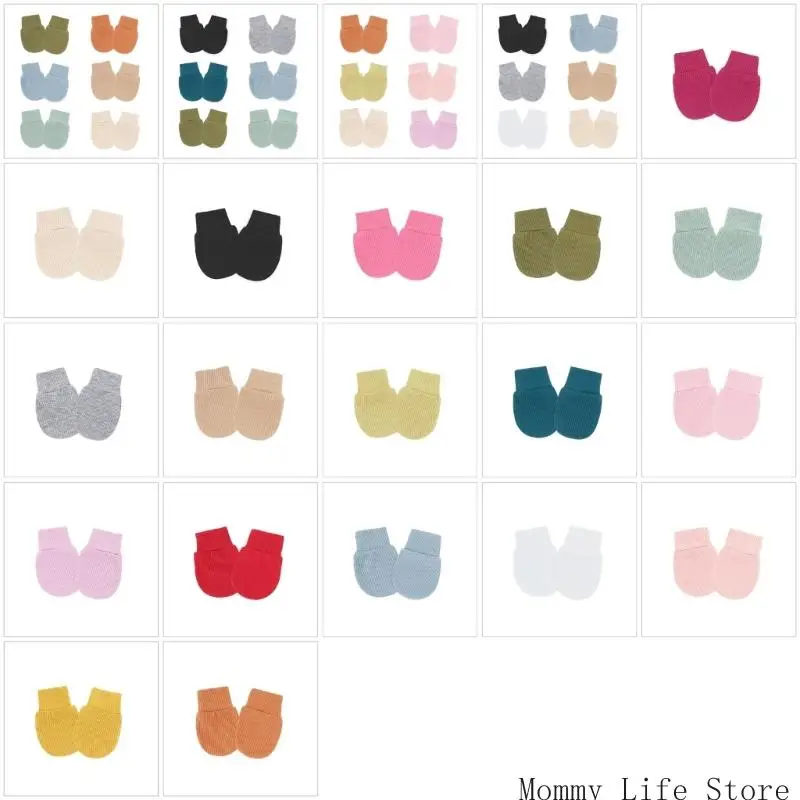

Elastic Wrist No Scratch Mittens Toddler Mitts for Boys Girls 0-12 Months Cotton Mittens Gloves Baby Breathable Gloves

aliexpress.com

$93.68

For 2005-2009 Hyundai Tucson Kia Sportage V6 2.7L 10PA17C 977012E100 977012E300 977012E301 977012E350 Aircon AC Compressor

aliexpress.com

$65.25

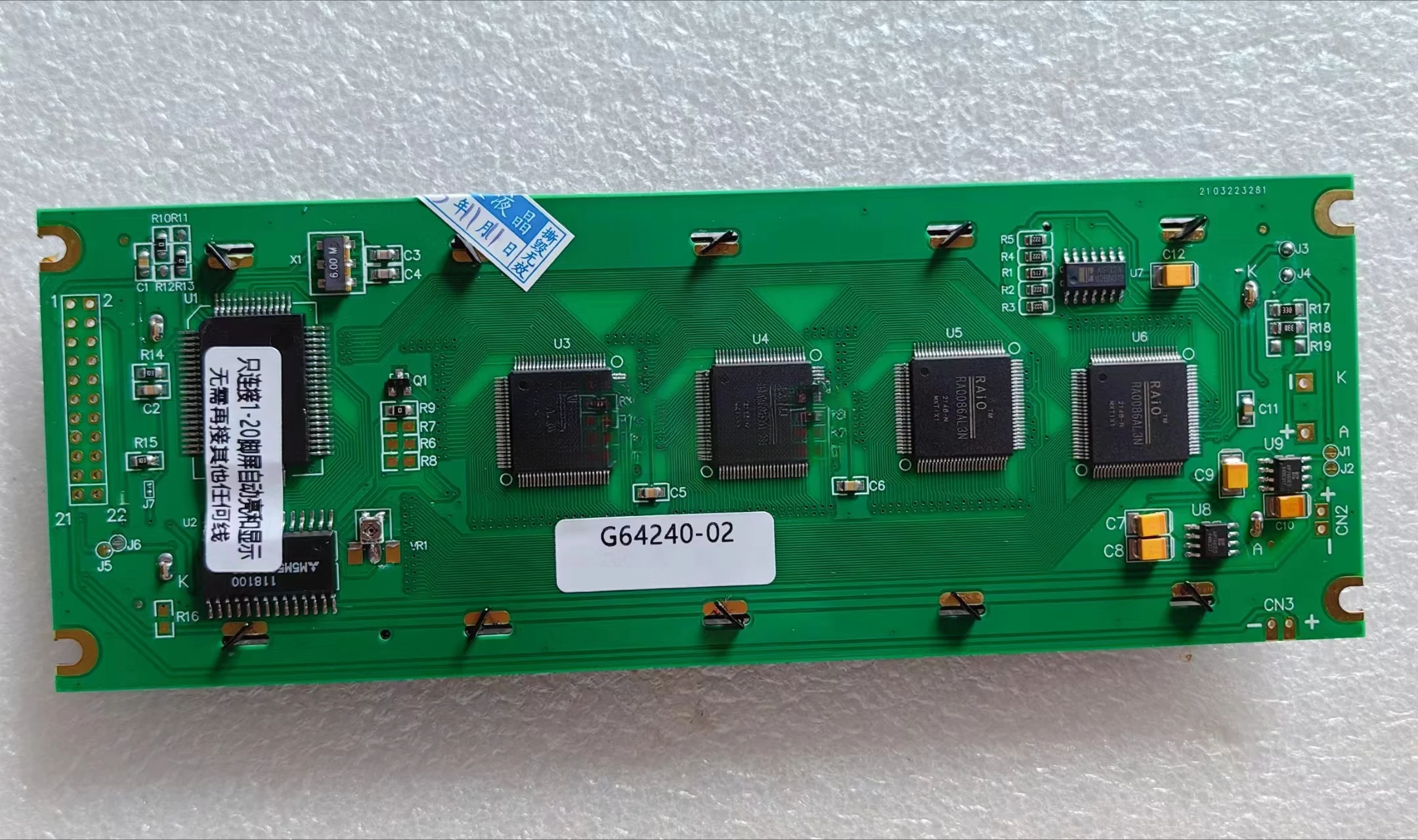

Compatible G64240-02 PB0017-01 22 Pin LCD Display Screen Panel Repair Repalcement

aliexpress.com

$604.56

N Buddhist niche new Chinese vertical cabinet household offering table Solid wood offering to the God of Wealth Shrine

aliexpress.com

$23.50

3D Artistic Bedding Set King Monet Van Gogh Style Sky Oil Painting Pattern Printed Duvet Cover With Pillowcases Hot Sale

aliexpress.com

$2.72

Persian Mini Woven Rug Mat Mousepad Carpet Pattern Cup Mouse Pad Fring Retro Style Home Office Table Decor Craft

aliexpress.com

$18.40

ORSA JEWELS Trendy Tree of Life 925 Silver Dangle Earrings with for Women with Multi-Colors CZ Earrings Jewelry Gift SE342

aliexpress.com

$3.86

Japan JoJo's Bizarre Adventure Anime Phone Case For iPhone 11 13 12 Pro Max 12 13 Mini X XS XR MAX SE 6 7 8 Plus Funda Black

aliexpress.com