Coaxial Centering Indicator Co-Ax Precision Milling Machine Test Dial + Stylus

BCLONG

sku: 2796788341

ACCORDING TO OUR RECORDS THIS PRODUCT IS NOT AVAILABLE NOW

$133.68

Shipping from: United States

Description

feature: High quality material durable center search indicator is a secondary measuring tool. Its technical indicators implement enterprise standards and serve as an auxiliary tool for machine tool alignment indicators. For various applications the measuring range is 0-3mm/0.12in equipped with different lengths and shapes of measuring rods to meet different requirements. The centering rod indicator is used to determine the relative position of the inner and outer centers to the center of the machine tool spindle. Rotate the shaft carefully so the indicator is always facing the operator. A centering gauge is a precision measuring instrument suitable for determining the position of workpiece components on vertical or horizontal machine tools. It can work on tables with motorized or manually turned machine tool spindles. scope: material: metal Size: as shown 3 types of centering indicator probes: 1. Straight probe 2. Curved probe 3. Point probe. Measuring range: 100/4 200/8 300/12 Imperial: Range 0.12in Readout: 0.0004in Imperial: Range 0.3mm Readout: 0.01mm Preparation before measurement: 1. Install the probe: screw in the fixing screw then insert the probe handle into the socket hole and tighten the screw to fix it. Using this method all probes can be easily replaced. 2. Install the fixing rod: There are three screw holes at the bottom of the chassis. To keep the dial facing the operator and to facilitate the positioning of the joystick the joystick can be screwed into one of the selected tapped holes. 3. Install the alignment indicator on the machine tool spindle chuck. 4. Install the workpiece to be tested on the machine table so that the object to be tested can be placed on the centering table. Axis rotation: 1. The spindle must be rotated during measurement. Spindle should be turned at minimum speed or manually for easy viewing. At this time the spindle speed of the machine tool should not exceed 800 rpm. 2. Before the spindle rotates the fixed rod must be blocked with a stick. Otherwise the entire centering indicator will rotate with the machine and the indicator will not always face the operator. Probe selection: 1. Inner circle centering: generally a straight probe should be used. For larger inner diameters larger probes should be selected. Curved probes can also be used when the diameter is greater than 25.4 mm (liters). 2. Outer circle centering: use a curved probe. Choose a large diameter probe. 3. Small holes with openings less than 3mm/0.12in and the center of the drilling mark : point probes can be used. Package includes: 1 * Centering gauge 3 * Straight Probe 3 Elbow 1 * Small hole probe 1 * Wrench 1 bracket 1 x Manual 1 box notes: Due to manual measurement please allow 1-2cm/0.39-0.79 error. The color of the item shown in the photo may be slightly different on the computer screen because the screen is not calibrated.

Price history chart & currency exchange rate

Customers also viewed

$1.30

30Sheet Retro Creative Decoration DIY Album Journal Notebook Scrapbooking Plant Craft Label Diary Stationery Album Stickers

aliexpress.com

$8.75

Держатель для стержня палатки, держатель для стержня, фиксированные укрытия, ветрозащитный фиксирующий Зажим, аксессуары для тента, палатки

aliexpress.com

$79.30

HIgh Full Sleeve Muslin Evening Dresses with Pleat 2023 New Satin Prom Gowns for Women Ankle Length Robe De Soirée Zipper Back

aliexpress.com

$40.86

Korea Strawberry Niacinamiden Emollient Translucent Body Mask 480g Whitening Moisturizing Brighten Rejuvenate Skin Care Products

aliexpress.com

$44.10

2X Oil Resistant Straight Squeegee,Rubber Squeegee Blades For Karcher BR 30/4C Cleaner

aliexpress.com

$1,165.32

Nordic Marble Dining Table Modern Simple Rectangular Home Dining Table Dining Table and Chair

aliexpress.com

$47.85

casual dresses cupnice knee-length dress knitted elastic sleeveless bodycon elegant women 2021 summer v-neck button party slim, Black;gray

dhgate.com

$4.20

1 Pair Bridal Gloves Lace Fashion Hollow Out Flower Dew Finger Bandage Gloves Dress Accessories Wedding Decorations

aliexpress.com

$10.37

APL-Strange Stainless Steel Pendant Men's Fashion Necklace Hollow Silver Gold Necklace Jewelry Gift

aliexpress.com

$2.15

Glass Spray Watering Can for Indoor Outdoor Plants Small Succulents and Flowers Lightweight Portable Retro Design Decorative

aliexpress.ru

$21.88

Летние женские сандалии на высоком каблуке 2025 года: универсальные, с ремешком на щиколотке, в римском стиле, с низким вырезом, из ПУ, удобные и модные

aliexpress.ru

$6.63

НОВЫЙ 1-метровый быстрый USB-кабель для зарядки Casio WSD-F10 WSD-F20 WSD-F30, зарядное устройство Pre-Trek F21, магнитный блок питания для часов

aliexpress.ru

$4.49

1 шт. Профессиональный многофункциональный инструмент для чистки сахарного тростника из нержавеющей стали, эргономичный кухонный гаджет для фруктов и овощей

aliexpress.ru

$25.02

Ультразвуковой увлажнитель воздуха, мини-ароматический увлажнитель, очиститель воздуха со светодиодной лампой, 4 л, увлажнитель воздуха, портативный генератор тумана для домашнего офиса

aliexpress.ru

$30.88

12 шт., наклейка на плитку из ПВХ, водостойкая наклейка на напольную плитку для ванной комнаты, имитация мрамора, клейкие обои, ламинированная наклейка на пол

aliexpress.ru

$13.75

Оригинальная ручка для головы, противоскользящие ручки для теннисной ракетки, аксессуар для падела, шок, теннис, бадминтон, сквош, тренировочная повязка

aliexpress.ru

$1.89

DN0SDN224 DN0SDN240 DN0SD304 DN0SD248 DN0SD126 DN10SD242 Производители деталей и компонентов сельскохозяйственной техники продают SD195

aliexpress.ru

$4.55

Светодиодный мини-сильный фонарик, прозрачный брелок, сверхлегкий портативный COB, боковой мягкий свет для кемпинга

aliexpress.ru

$4.60

Главный переключатель управления электрическим стеклоподъемником спереди слева/правый для Honda Accord 2003, 2004, 2005, 2006, 2007 35760SDAA21 35750SDNA03

aliexpress.ru

$6.87

Детские рюкзаки для футбола RB L-LeipzigS, сумка на плечо, пенал, школьные сумки большой вместимости для мальчиков и девочек, лучший подарок

aliexpress.ru

$1,708.30

Морозильная камера S3 с воздушным охлаждением, -45 градусов, для быстрой заморозки: для морских огурцов, пельменей, паровых булочек, замороженных полосок

aliexpress.ru

$7.28

Футболка с принтом ретро-Супермена, модный топ с короткими рукавами и принтом Лиги справедливости для мужчин и женщин, повседневная и стильная одежда на каждый день

aliexpress.ru

$2.04

DOHOHDO Y2k New Punk Sports Sunglasses For Men Women Luxury Brand Designer Sun Glasses Men's Vintage Shades UV400 Goggle Eyewear

aliexpress.ru

$27.75

Indoor home aromatherapy fragrance diffuser gift ornament, car fragrance lasting sandalwood home fruit fragrance

aliexpress.ru

$141.33

Ночная сорочка из 100% шелка тутового шелкопряда с поясом, пышная юбка, элегантная ночнушка, пижама с длинным рукавом, ночная рубашка с рюшами и кружевом, ночная сорочка в стиле принцессы

aliexpress.ru

$659.94

Black solid wood chest of drawers, living room storage porch, bedside storage cabinet

aliexpress.ru

$200.53

Новый 13-дюймовый FPV-дрон для гонок: комплект рамы с лучами толщиной 8 мм, аксессуары для дронов

aliexpress.ru

$2.69

10/50PCS Cartoon Cool Scissor Seven Stickers Doodle Toy Stickers for Computer Desktop Pencil Box Wardrobe Guitar Suitcase Bike

aliexpress.ru

$4.49

Baby Reins Sleeveless Zip-up Pocket Baby Walking Harness Anti-Lost Kids Comfortable Safety Children Reins for Toddlers Boys Girl

aliexpress.ru

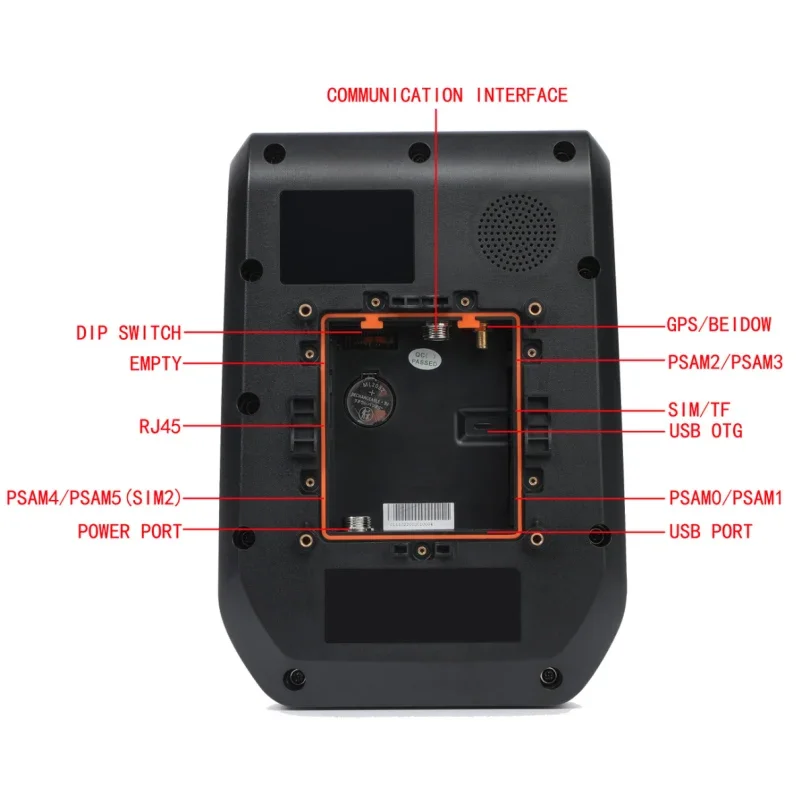

$609.64

Модуль-валидатор билетов для общественного транспорта 2026: Сканер штрих-кодов, считыватель штрих-кодов Arduino, электронные компоненты

aliexpress.ru

$86.61

ZJCGO 4K Car DVR Dash Cam Wifi Front Rear Camera 24h Monitor for Ford Kuga Escape 2013 2014 2015 2016 2017 2018 2019

aliexpress.ru

$14.90

ODORZ GISSAH LA LUNA VALLEY 200 мл - Духи для женщин и мужчин - Парфюмированная вода | Стойкий парфюм премиум-класса от Qissah

aliexpress.ru

$18.27

Новые женские джинсы с высокой талией, прямые, синие, больших размеров, эластичные, утягивающие, французские брюки-«багеты», узкие брюки-«трубы» малого размера

aliexpress.ru

$15.21

Портативная ручная точилка для бензопилы, ручная цепная шлифовальная машина, прочная, простая в использовании для заточки цепей бензопилы

aliexpress.ru

$11.73

2 шт. R410A Адаптер переменного тока SAE с внешней резьбой 1/4 для заправочного шланга, насоса, латунь 5/16 SAE 1/4 SAE, наружная резьба для инструмента системы клапанов

aliexpress.ru

$20.14

2200MAH NP-95 NP95 DB-90 DB90 Battery for Fujifilm X30 X100 X100S X100T X-S1 for FinePix F30 F31 Fd F31fd Real 3D W1 FNP-95

aliexpress.ru