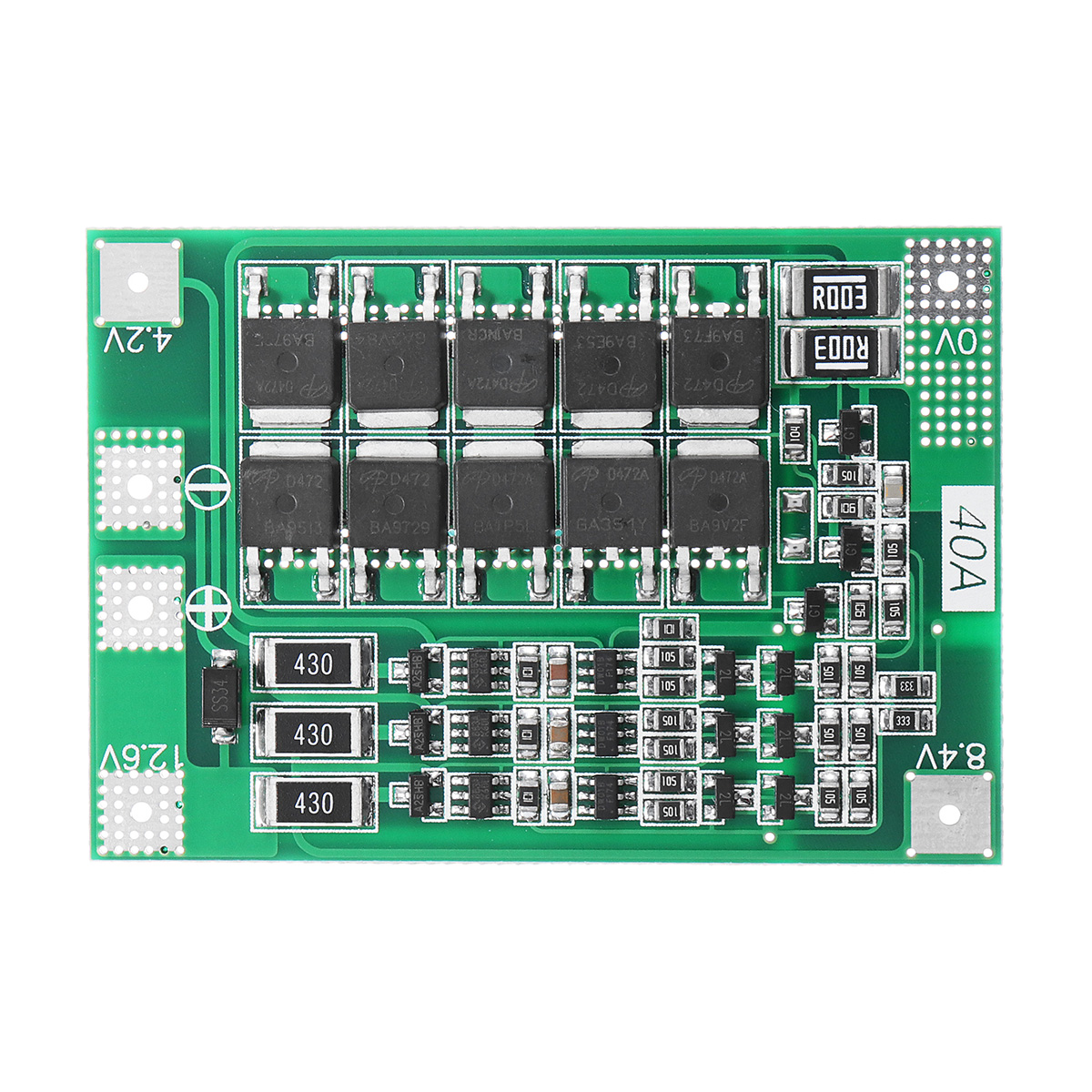

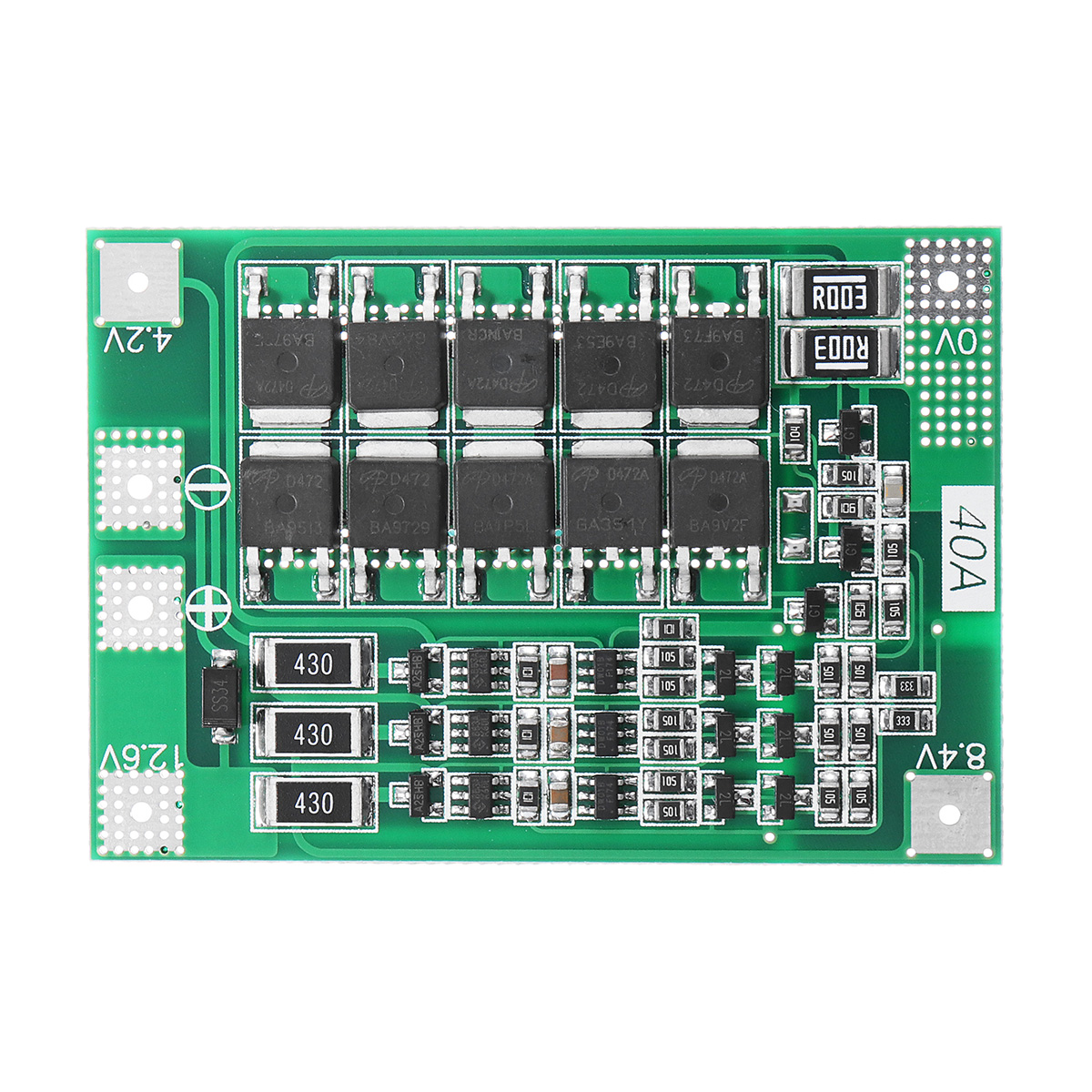

3S 40A Li-ion Lithium Battery Charger Protection Board PCB BMS For Drill Motor 11.1V 12.6V Lipo Cell Module With Balance

Eachine1

sku: 1394450

ACCORDING TO OUR RECORDS THIS PRODUCT IS NOT AVAILABLE NOW

$2.49

Shipping from: China

Description

Description: Suitable for starting current below 80A, power 135W below the drill. (with balance) 3S 12.6V 40A lithium battery protection board (comes with recovery function-AUTO Recovery) Scope: Nominal voltage of 3.6V, 3.7V lithium battery (including 18650,26650, polymer lithium battery) Product Size: 41 * 60 * 3.4mm Product weight: 9.8g Charging voltage: 12.6V - 13.6V Continuous discharge current (upper limit): 40A (if the cooling environment is not good, please reduce the load current use) Continuous charge current (upper limit): 20A Note 1: The successful start of the drill requires three 15C-20C power battery, or six 10C-15C power battery (ordinary 18650 cannot start the drill..). Note 2: Strictly according to map wiring 0V, 4.2V, 8.4V, 12.6V, do not deliberately short circuit. Note 3: When soldering the battery for the first time or while charging, as long as the single battery exceeds 4.2V, the "430" resistor will heat up and discharge (discharge to about 4.19V to stop heating). If the "430" resistor is severely hot, check if the wrong line is connected. For some of the poor basis of electronic customers to explain: Balanced charge is only auxiliary functions, try not to put a good battery and poor battery mixed together. 3 sets of battery capacity / resistance closer to the better. (2 good battery +1 Poor battery use effect = 3 poor battery use effect). Project Min. Typ. Max. Units Notes Consuming current 12 18 24 uA Overcharge protection voltage 4.2 4.25 4.3 V Balanced starting voltage 4.17 4.2 4.23 V Balanced version Equilibrium current 95 100 105 mA Balanced version Balanced heating power 1.17 1.29 1.43 W Balanced version Overcharge recovery voltage 4.1 4.15 4.2 V Over-discharge protection voltage 2.4 2.5 2.6 V Overvoltage protection after over-discharge protection 2.8 3 3.2 V 1C discharge Overvoltage protection after over-discharge protection 3.2 3.5 3.8 V 2C discharge Over-discharge recovery voltage 2.9 3.2 3.3 V Conduction internal resistance 2.5 3 3.5 mQ Overcurrent protection current 70 80 90 A Overcurrent delay time 100 150 200 ms Continuous operating current 0 40 40 A Resistive load Continuous output power 0 504 504 W Resistive load Ambient temperature -40 25 85 C Package includes: 1 x Battery Protection Board Troubleshooting: Fault phenomenon Fault check and cause Approach Unable to charge Measure the voltage of the three groups of batteries. If one of the battery voltages exceeds 4.25V, the protection board will activate overcharge protection. Pair the battery pack well, do not mix the good battery and the bad battery (normal function) Unable to discharge Measure the voltage of the three battery packs. If one of the battery voltages is lower than 2.7V, the protection board will activate the over- discharge protection. Pair the battery pack well, do not mix the good battery and the bad battery (normal function) Charging/discharging failure OV, 4.2V, S.4V, 12.6V miswired Rewiring or replacing a new board (human failure) Overcharge/overdischarge failure OV, 4.2V, 8.4V, 12.6V miswired Rewiring or replacing a new board (human failure) Discharge protection Check that the battery pack has sufficient discharge capability and check that the load's starting current exceeds the overcurrent protection current of the protection board. Replace the battery pack with a higher discharge capacity, or a protective plate with a larger current (super working range) Component soldering There is no connection between one of the components and the PCB pad. Repair welding Component welding There is a short circuit between two or more pins of the component. Remove the component and re-weld Electrostatic breakdown A In the unpowered state, measure the G, D, and S poles of the MOSFET. If the forward and reverse resistances of any two pins are 0Q, it indicates that it has broken down. Remove the replacement MOS tube Electrostatic breakdown B Remove the MOS tube and measure the resistance of the G and D, G and S poles of the MOS tube. If there is a resistance indicating that it has broken down, the resistance should be infinite. Remove the replacement MOS tube

Price history chart & currency exchange rate

Customers also viewed

$110.43

Постельное белье 200х220 см. Комплект из 3 предметов, коричневый, 100 % хлопок/Renforce Vega V2 Yadetextil

cdek.shopping

$4.01

Multi Soldering Helping Hand Tool Table Clip Third Hand Soldering Stand Welding PCB Holder Flexible Arm Soldering Tool

aliexpress.com

$1.88

2024 New Winnie the Pooh Bear Stud Earring Cartoon Epoxy Jewelry Resin Acrylic Earrings Handmade Gifts Girl

aliexpress.com

$6.67

Винтажная толстовка с капюшоном с защитой от ультрафиолета, мужские модные толстовки большого размера, Детская Готическая Толстовка в стиле хип-хоп, Женская толстовка с защитой от пота, пальто в стиле рок для мальчиков

aliexpress.ru

$2.69

Natural 100% African Black Soap Magic Anti Rebelles Body Acne Beauty Bath Care Skin Treatment Soap Net

aliexpress.com

$16.68

VEZFAA Женская мода Повседневный Лето Весна Цветочный Узор Принт Короткие рукава V-образный вырез Блузки и рубашки S белый

joom.ru

$51.26

sport bikini push up swimwear women high waist swimsuit knotted beachwear dstring bathing suit boyleg biquiniby air

dhgate.com

$4.29

5D Алмазная мозаика, домашний пейзаж с цветами, полноразмерная вышивка крестиком, полноразмерная круглая алмазная живопись, украшение для т...

aliexpress.ru

$26.43

men's t-shirts side striped gym men cotton slim short sleeve sports bodybuilding fitness mens workout tees, White;black

dhgate.com

$6.51

Щетка углеродная с электродвигателем и вакуумным двигателем 4X 2311480 333261-1 для инструментов Ametek Lamb Mar

aliexpress.ru

$16.99

Сменные протеиновые кожаные амбушюры с пенным наполнителем с эффектом памяти, амбушюры, накладки для наушников, запасные части для наушник...

aliexpress.ru

$87.17

boots kemekiss women high heel long zipper thick knee fashion winter shoes woman footwear size 34-43, Black

dhgate.com

$17.38

women's shorts tingfly plus size high waist elastic band pockets pu leather casual short pants women autumn winter black, White;black

dhgate.com

$232.53

suitable for - c-class w205 interior speaker cover midrange cover ambient light interior lighting modification

dhgate.com

$5.65

Мешок для обуви Berlingo Flamingo style, Разноцветный, Мешок для обуви Berlingo Flamingo style

mytoys.ru

$42.93

Red beans Hodo men's sweaters men's fashion Slim solid color round men's sweater B1 blue 185 / 100A

joybuy.com