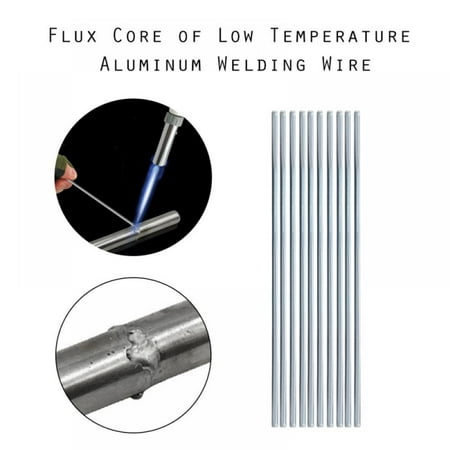

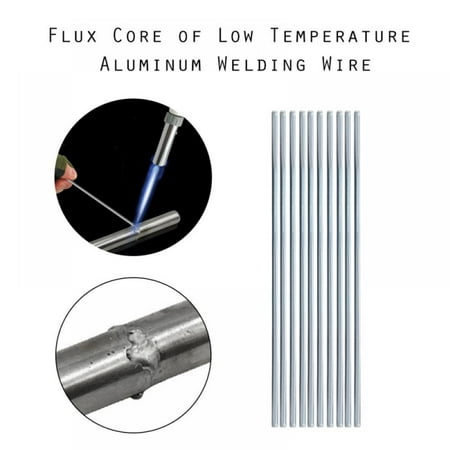

Clearance sale! Welding Rods - From Simple Solution Now - Aluminum Brazing/Welding Rods - Make Your Repair Stronger Than The Parent Metal Every Time - 10 Rods

ZeHui986

sku: 971804631

ACCORDING TO OUR RECORDS THIS PRODUCT IS NOT AVAILABLE NOW

$14.25

Shipping from: United States

Description

Product Description: Material:Aluminum Color:Silver Number of Pcs:10PCS 20PCS 50PCS Melting Point:647°~658° Diameter:2mm / 0.08 Length:500mm / 19.7 Weight:Approx. 3.5g / 0.12in (One Aluminum Welding Wire) Features: Great Welding Effect: With full & smooth welding effect because of internal powder. With low melting point(647°~658°) great weldability and corrosion resistance high thermal conductivity high electric conductivity and excellent processing performance. No Need Solder Powder: You don t have to use other flux powder with aluminum alloy as the welding core and coating as the salt base. Very convenient and easy to weld. Widely Use In Life: Suitable for welding or surfacing welding alloy with high strength good forgeability & good corrosion resistance. Very Wide Application: It is mainly used for argon arc welding and filling material for pure aluminum connection with aluminum bus and guide rod of electrolytic aluminum plant and electric power chemistry food and so on. Light Weight & Small Volume: Size of 500 x 2mm & weight of 3.5g very easy to bend & carry. Recommended for welding or brazing aluminum alloy: 1060 1350 3003 3004 3005 5005 5050 6053 6061 6951 7005 and cast alloys 710.0 and 711.0 Package Included: 1 SET Aluminum Welding Wires How to Use: Step 1: Clean and polish the physical surface. Step 2: Heat the surface of the base material until the temperature of the wire to the operating temperature of 380°~400° so you can rely on the parent metal heat transfer welding wire to form welds should not use the flame to burn wire When the surface temperature of the base metal is sufficient the wire can flow well and penetrate into the metal capillary. Step 3: When repairing thin aluminum as long as the aluminum base metal heated to the appropriate working temperature and then use the wire back and forth friction melting to form a weld only with a metal brush melt welding wire to weld at the weld.

Price history chart & currency exchange rate